In the past years since we started selling our drone test stand technology, we've learned a lot of lessons through trial and error.

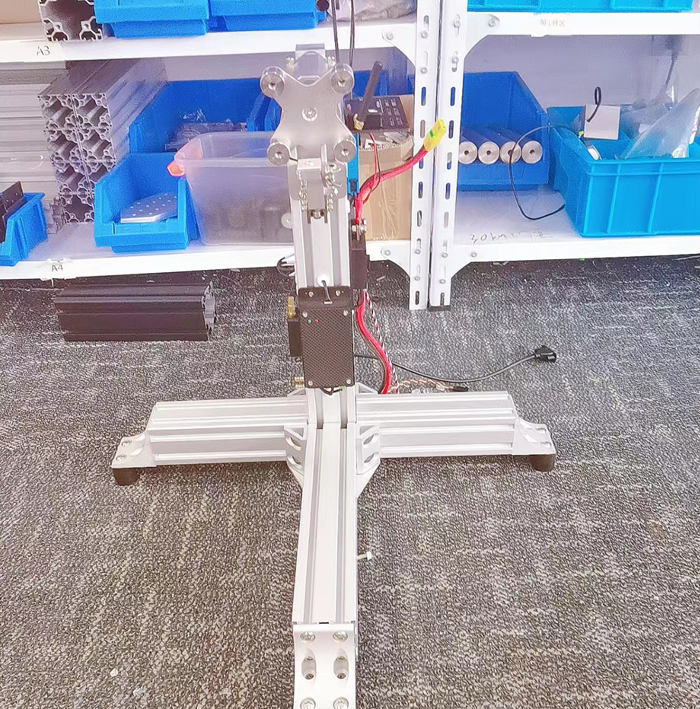

If you are familiar with our products, then you know that our test thrust stands combine thrust and torque measurements with voltage and current to derive the system’s power and efficiency.

Perhaps the most obvious concept for such a tool, and the cheapest to build, is a system involving bearings or bushings.

What we've learned, however, is that using bearings and bushings has a number of disadvantages:

1. Bearings and bushings cause friction. The random friction error causes significant uncertainty in the measurement (anywhere from 2 to 20% of the measured force). Even if the design looks rigid, there are micro deformations and movements in the system.

2. This leads to hysteresis in the force measurement: the force measured is dependent on the previous force applied. Because of the random nature of friction, it is not possible to correct for the error.

3. Another problem with bearings or bushings is that they are very sensitive to misalignment. A small shock, dust or dirt can cause a false reading. The error is not constant due to the random elements that affect it (friction, dust, etc.), so it can not be accounted for consistently.

In addition to our early tools, we noticed that many hobby thrust stands and homebuilt designs used bearings had the same issues.

There are disadvantages to using a solid state system, such as:

● More analysis is required, as the entire load is directly on the force measurement unit. The unit will be more fragile if it is not designed for the side loads and the expected ranges of torque and thrust.

● The design has to be done carefully to reject thermal expansion effects on the load cells.

● Multiple other difficulties related to assembly, minimization of internal forces, and manufacturing.

The only way to address these issues was with simulations and many experimental tests. The tests we performed included calibration and verification with hundreds of points, endurance testing, and hundreds of hours of motor testing.

Overall, given our experience, we strongly recommend that any thrust and torque measurement tool use a solid state design without pivots or bearings. In a professional environment, losing months of tests due to faulty data can be extremely expensive. The tests have to be redone and the product may be delayed. There is also a recall risk if the faulty data is used in production.

If you'd like to learn more, feel free to contact Wing Flying.