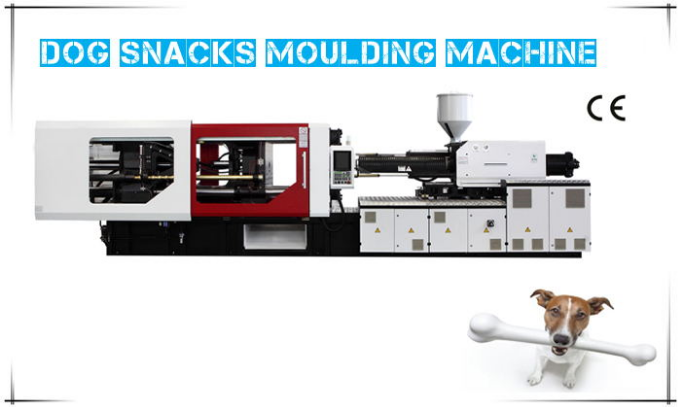

A dog snacks molding machine is a specialized piece of equipment used in the production of dog treats or snacks. Its primary function is to mold or shape ingredients into various forms that can be served as treats for dogs. These machines play a crucial role in the pet food industry by enabling the efficient and consistent manufacturing of a wide range of dog snacks in different shapes, sizes, and textures.

Design and Functionality:

Dog snacks molding machines come in various designs and sizes, ranging from small-scale units suitable for home-based operations to large-scale industrial machines used in commercial pet food manufacturing facilities. The basic components and functionalities of these machines typically include:

1. Mixing and Blending: Ingredients such as flours, meats, vegetables, fats, binding agents, vitamins, and minerals are mixed together in specific proportions to create a dough or mixture suitable for molding. The blending process ensures a homogenous mix of ingredients.

2. Molding Mechanism: This is the core part of the machine responsible for shaping the treat. Different molding techniques are employed, including:

- Extrusion: Involves pushing the prepared mixture through a shaped opening or die to create uniform shapes like bones, sticks, or pellets.

- Pressing: Uses molds or presses to shape the mixture into specific designs, such as paw prints, hearts, or other unique shapes.

3. Baking or Drying (Optional): Some machines include baking or drying capabilities to cook or dehydrate the treats, enhancing their texture, flavor, and shelf life. This step may involve passing the molded treats through an oven or a drying chamber.

4. Cooling and Packaging: Once the treats are molded and treated, they are cooled down to room temperature. Then, they are typically packaged in bags, boxes, or other containers for distribution and sale.

Materials Used:

The ingredients used in dog snacks vary widely and can include various types of flour (like wheat, rice, or barley), proteins (such as meat meals or plant-based proteins), fats, flavorings, and additives (like vitamins or preservatives). The selection of ingredients depends on the desired nutritional content, flavor, and texture of the final product.

Benefits and Importance:

Dog snacks molding machines offer several advantages:

- Efficiency: They streamline the production process, allowing for high-volume manufacturing with consistent quality.

- Customization: These machines enable the creation of treats in diverse shapes, sizes, and textures, catering to different preferences and dietary needs of dogs.

- Quality Control: Manufacturers can ensure precise ingredient measurements and hygienic production conditions, meeting regulatory standards for pet food safety.

These machines are essential for pet food manufacturers, allowing them to meet the increasing demand for a variety of dog treats in the market. Moreover, they provide pet owners with a convenient way to offer their dogs nutritious and appealing snacks.

Maintenance and Care:

Regular maintenance is crucial to ensure the proper functioning of dog snacks molding machines. Cleaning, sanitizing, and routine inspections of the equipment prevent contamination, ensure product safety, and prolong the machine's lifespan.

Conclusion:

In summary, a dog snacks molding machine is a specialized device that plays a pivotal role in the production of dog treats. It facilitates the efficient and consistent manufacturing of a diverse range of snacks, meeting the demands of both manufacturers and pet owners while providing quality treats for canine companions.