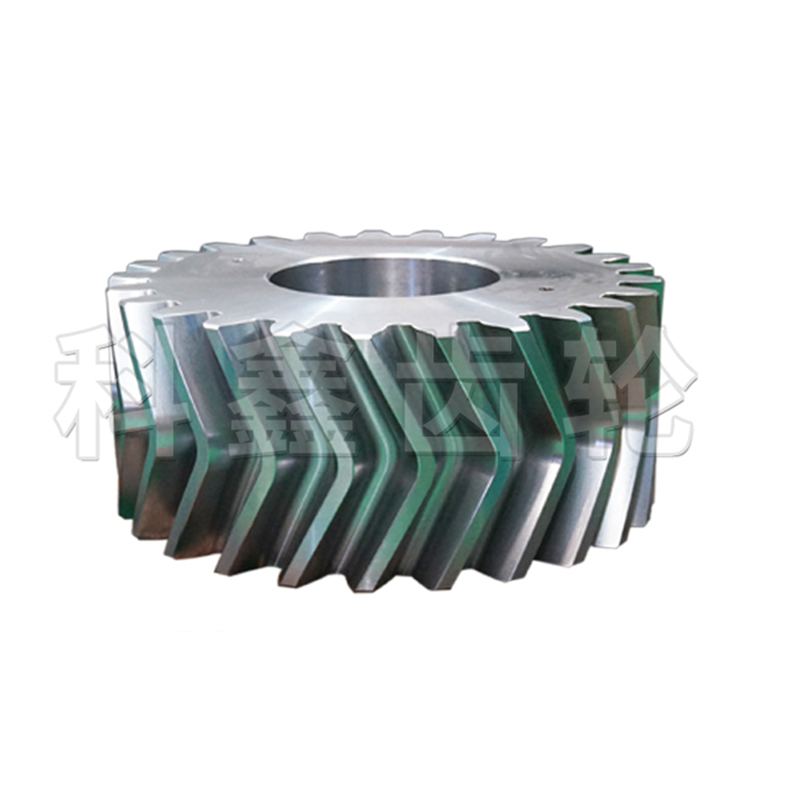

In the realm of mechanical engineering, precision and efficiency are paramount. Among the many components that contribute to the smooth operation of machinery, herringbone gears stand out as a pinnacle of innovation and functionality. With their unique design and impeccable performance, herringbone gears offer a multitude of advantages that elevate them above traditional gear systems. Let us delve into the intricacies of herringbone gears and unravel the main advantages they bring to various applications.

Enhanced Stability and Smooth Operation

One of the most prominent advantages of herringbone gears lies in their superior stability and smooth operation. Unlike conventional spur gears, which are prone to axial thrust and vibration, herringbone gears feature a double helical design that effectively cancels out these undesirable effects. This inherent balance ensures consistent and reliable performance, making herringbone gears ideal for applications where precision and smoothness are critical.

Minimized Noise and Vibration

In addition to their exceptional stability, herringbone gears offer another significant advantage in the form of minimized noise and vibration. The symmetrical arrangement of the gear teeth results in smoother meshing action, reducing the impact of noise and vibration generated during operation. This makes herringbone gears particularly well-suited for environments where noise pollution is a concern, such as industrial settings or precision machinery applications.

Increased Load-Bearing Capacity

Another key advantage of herringbone gears is their increased load-bearing capacity compared to traditional gear designs. The double helical arrangement distributes the load more evenly across the gear teeth, allowing herringbone gears to withstand higher torque and pressure without succumbing to failure. This enhanced durability and strength make herringbone gears a preferred choice for heavy-duty applications where reliability is paramount.

Improved Efficiency and Power Transmission

Efficiency is a hallmark of herringbone gears, thanks to their optimized design and precision engineering. The symmetrical tooth arrangement minimizes friction and ensures smooth power transmission, resulting in less energy loss and greater overall efficiency. Whether used in automotive transmissions, industrial machinery, or aerospace applications, herringbone gears excel in delivering power reliably and efficiently.

Versatility in Design and Application

The versatility of herringbone gears is yet another advantage that sets them apart in the realm of mechanical engineering. Their robust design and adaptable nature make them suitable for a wide range of applications, from simple gearboxes to complex drivetrains. Whether used in horizontal or vertical configurations, herringbone gears offer unparalleled flexibility and performance, making them indispensable in diverse industries.

Conclusion

In conclusion, herringbone gears represent a pinnacle of engineering excellence, combining precision, efficiency, and reliability in a single innovative design. Their enhanced stability, minimized noise and vibration, increased load-bearing capacity, improved efficiency, and versatility make them indispensable components in various mechanical systems. By harnessing the advantages of herringbone gears, engineers and manufacturers can unlock new levels of performance and functionality across a myriad of applications.