Color coated steel coils have emerged as a versatile and popular material in various industries, owing to their exceptional characteristics and wide-ranging applications. In this article, we will delve into the advantages of color coated steel coil and explore the diverse fields where they are extensively used.

Understanding Color Coated Steel Coil

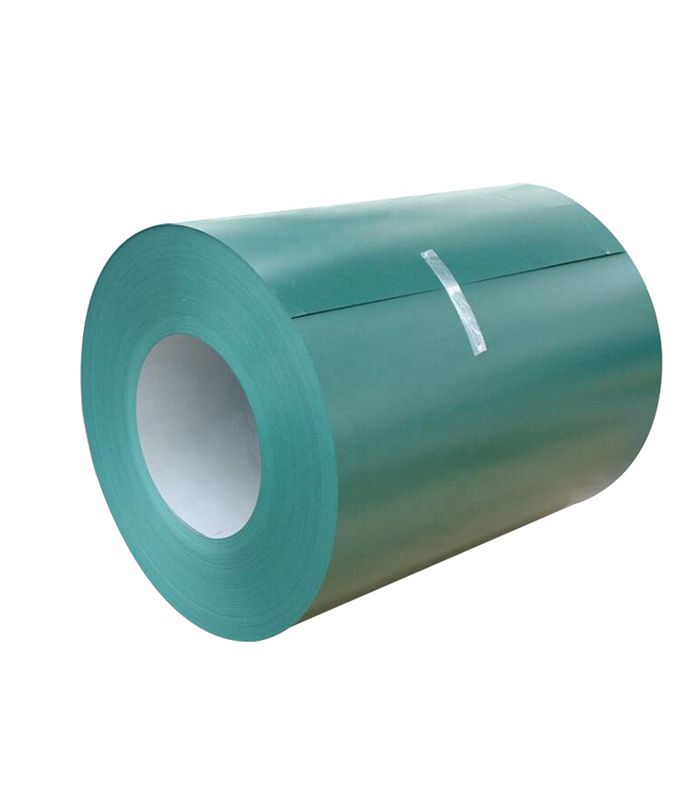

The Process of Color Coating

Color coated steel coils are created through a process known as coil coating or pre-painting. In this process, a layer of paint or resin, containing pigments of different colors, is applied to the surface of the steel coil. The coated coil is then oven-baked to ensure the adhesion of the paint and form a durable and vibrant colored finish.

Types of Coating Materials

Various types of coating materials are used in color coated steel coils, including polyester, silicon modified polyester, polyvinylidene fluoride (PVDF), and polyurethane. Each type offers distinct properties, such as weather resistance, corrosion resistance, and flexibility.

Advantages of Color Coated Steel Coil

1 Aesthetic Appeal

The primary advantage of color coated steel coils is their aesthetic appeal. The wide array of colors and finishes available allows architects, designers, and manufacturers to create visually striking and attractive products and structures.

2 Enhanced Durability

Color coated steel coils are highly durable and resistant to fading, chipping, and cracking. The protective coating shields the steel from environmental elements, ensuring longevity and reducing maintenance costs.

3 Corrosion Resistance

The coating on color coated steel coils acts as a barrier against moisture and corrosive substances, providing excellent protection against rust and corrosion. This makes them ideal for applications in humid and corrosive environments.

4 Energy Efficiency

Color coated steel coils with reflective coatings can help improve energy efficiency in buildings by reflecting sunlight and reducing heat absorption. This, in turn, can lead to lower cooling costs.

5 Lightweight and Strong

Color coated steel coils are lightweight yet sturdy, making them easy to handle and transport while maintaining structural integrity and strength in various applications.

Applications of Color Coated Steel Coil

Construction and Architecture

Color coated steel coils find extensive use in the construction industry for roofing, wall cladding, and exterior facades. Their aesthetic appeal and durability make them a preferred choice for modern architectural designs.

Automotive Industry

In the automotive sector, color coated steel coils are used for various components, including car body panels, trims, and interior parts. The versatility of colors allows car manufacturers to meet diverse customer preferences.

Appliances and Electronics

Home appliances and electronics often feature color coated steel coils, adding a touch of style and elegance to products such as refrigerators, washing machines, and ovens.

Transportation and Shipping

Color coated steel coils are employed in the transportation and shipping industries for manufacturing containers, trailers, and cargo structures. The protective coating ensures resistance to wear and tear during transportation.

Signage and Branding

The vibrant colors and weather resistance of color coated steel coils make them an ideal choice for outdoor signage and branding applications.

Conclusion

Color coated steel coils offer a perfect blend of aesthetics, durability, and versatility, making them an attractive choice for a wide range of applications. Their advantages, including aesthetic appeal, enhanced durability, corrosion resistance, energy efficiency, and strength, have made them a go-to material in various industries.

From construction and automotive to appliances and transportation, color coated steel coils have revolutionized the way we design, build, and manufacture products. Embrace the advantages of color coated steel coils and elevate your projects and products with vibrant and durable finishes that leave a lasting impression.